DTF film (Direct to Film film) has a bit of mystery around it....

1. how does ink stick to it

2. how is the image released from it when pressed?

The film itself needs to be manufactured with specific properties to make the process successful. Now PET has been around since the 1950s used in various applications, from clothing to containers to engineered resins, and now DTF Film. PET is the fourth-most produced polymer in the world. Just to give you a little history.

Let's dive into how the magic of DTF Film is made.

What Is DTF Film Made Of?

DTF film is usually made from PET (Polyethylene Terephthalate) — a type of plastic known for its durability, heat resistance, and smooth surface. But it's not just regular PET film; it goes through a coating process to allow ink and adhesive powder to adhere properly.

Here's How DTF Film is Made:

-

Base Film Production (PET Film Creation):

- Raw materials (ethylene glycol and terephthalic acid) are polymerized to form PET.

- The molten PET is extruded into sheets and cooled to form the base film.

- This base film is typically 75–100 microns thick.

-

Surface Treatment:

- The PET film undergoes corona treatment or flame treatment to increase surface energy, which improves adhesion of coatings.

- This step makes sure the film can hold the special coatings and inks used in DTF printing.

-

Coating Application:

-

A release coating is applied to one side of the film.

- This is a special layer that allows the printed design to release cleanly from the film during heat transfer.

- Some films also get an antistatic or anti-curling layer on the other side for better handling. For example your matte / matte finish provides less static during the application process.

-

A release coating is applied to one side of the film.

-

Drying and Curing:

- The coated film is passed through a drying tunnel to cure the coating.

- The result is a matte or glossy finish depending on the desired product.

-

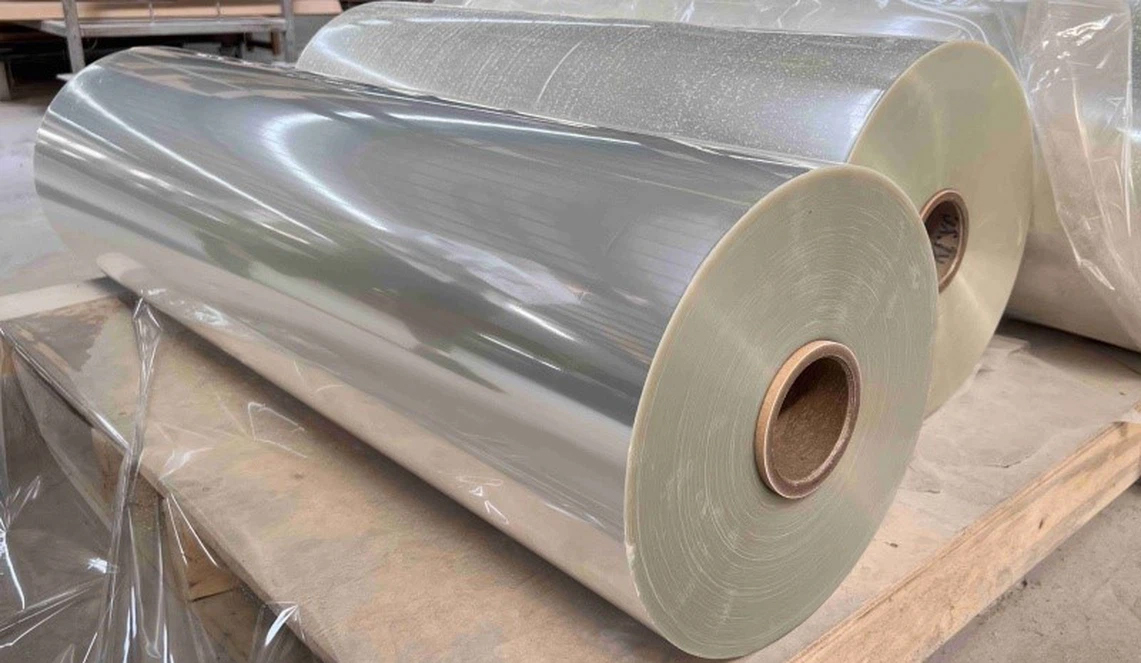

Cutting and Packaging:

- The large rolls are cut into sheets or smaller rolls.

- They're packaged in dust-free environments to prevent contamination. The better the manufacturer is about the packaging and storage of the film, typically the better consistence there is with the final product.

Key Characteristics of Quality DTF Film:

- High ink absorption without smudging

- Uniform coating thickness

- Good release ability after heat pressing

- Stability under heat and pressure

- Compatible with water-based pigment inks